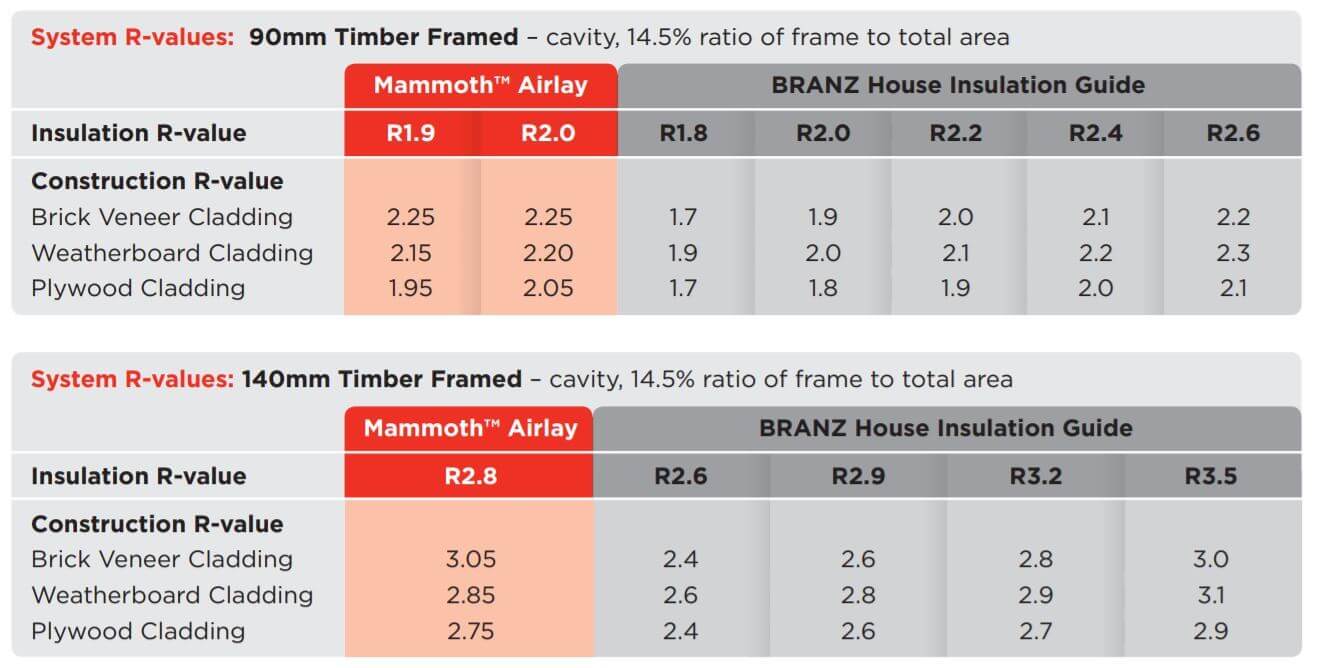

The New Zealand Building Code energy efficiency requirements are based on the system performance of building components rather than R-Value of individual elements, such as insulation. The laboratory tested R-value of wall insulation is not necessarily an accurate reflection on its ‘real life’ installed performance.

Construction R-value is a combination of the R-values of the individual components, including the effects of thermal bridging of the framing.

In order to realise its true performance, wall insulation MUST:

* BRANZ House Insulation Guide

InZone Industries Ltd has the only Airlay insulation manufacturing plant in Australasia producing medium and high density thermal and acoustic insulation.

The Mammoth® wall insulation produced on the Airlay plant is different to traditional carded polyester or fibreglass insulation. The springy nature of Airlay medium density insulation means it squeezes into wall cavities to be self-supporting, uncompressed and gap-minimising. It performs exceptionally well in wall and underfloor systems. Download a copy of our brochure here.

To prove and document the performance of Mammoth Airlay insulation, New Zealand’s leading building research laboratory was commissioned to undertake comprehensive independent insitu testing.

Conducted over the winter period June - July 2014, measurements were made using heat flux transducers and associated software developed and calibrated by New Zealand’s leading building research laboratory.

Test walls were 1.2m wide by 2.4m high with 90mm deep timber framing. The walls were installed in a research building and had three different types of cavity cladding:

Peace of Mind - when performing H1 calculations, specify the tested Mammoth Airlay Wall insulation with confidence, knowing that the wall construction R-Value will outperform the generic averages for equivalent systems.

Download the Mammoth Airlay Insulation brochure for more details.

Mammoth® Modern Insulation

Manufactured by InZone Industries Ltd

PO Box 204 289

Highbrook

Auckland 2161

New Zealand

Email:

info@mammoth.co.nz

Call Us:

0800 MAMMOTH

(0800 626 668)

• Send us a

Tweet

• Join us on

Facebook

• Follow us on

Instagram

• Follow us on

LinkedIn

If you need more information on Mammoth insulation for your home or next project, contact us on 0800 626 668 or email us at info@mammoth.co.nz